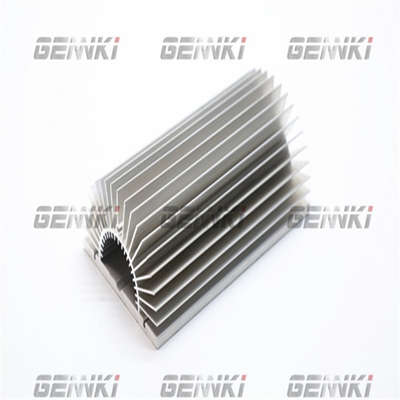

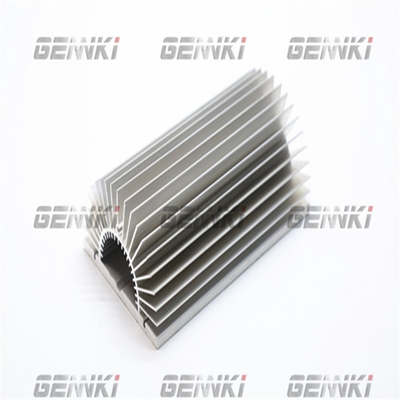

T3 - T8 6063 Aluminum Plastic Extrusion Mold PVDF Injection Moulding And Extrusion

| Shaping Mode | Aluminum Extrusion | Alloying Ingredient | 6063/6463/6061/6005 |

|---|---|---|---|

| Finishing | Anodizing, Powder Coating, Etc | Transport Package | Protective Tape |

| Application | Transportation Tools, Assembly Line, Workbench, Co | Color | Custom-made |

| Standard | ISO | Incoterm | FOB |

| High Light | T3 - T8 Plastic Extrusion Mold,6063 Aluminum Plastic Extrusion Mold,PVDF injection moulding and extrusion |

||

Fabricators are highly skilled professionals. They use the extrusion process for creating both solid and hollow sections.

There are several types of extrusion processing. The most common are cold, hot, friction and extrusion. During hot extrusion, fabricators force metal through a die with a ram.

Cold extrusion encompasses forcing metal through a die near or at room temperature. The metals used for this process come in large slugs.

With this method, once a fabricator loads the metal billet or slug into the die feeder, they use pressure to join them together. This step creates a solid object and a new shape or end product.

Fabricators commonly use several metals in the cold extrusion process. These metals include:

- Aluminum

- Copper

- Lead

- Niobium

- Steel

- Tin

As the fabricators press the metals into shape, the raw materials can heat up to several hundred degrees. This change in temperature is called deformation heating.

Deformation heating is when a metal increases in temperature as it expands or contracts. It’s essential to understand this process. This change in temperature can change the composition of the raw material.

| industrial aluminum profile, aluminum extrusion | |

| Material | T3 - T8 6063 aluminum alloy etc. |

| Surface treatment | Can be customized, such as Mill finished, Anodized, Electroplating, Powder-coated, Painted, Silver matt, Sand blasted, PVDF etc. |

| Aluminum Profile Size | 15/20/30/40/45/50/60/80/90/100/160 series etc. |

| V Slot, T Slot size | 6mm,8mm,10mm |

| Color | Standard: black, silver and grey. Can be customized (RAL color numbers) |

| Surface | Mill finish, Anodizing, Sand Blasting, Powder coating, etc. |

| Deep processing | Cutting Size, Drilling holes, Adding mounting bracket, Flanged side panels, etc. |

| Application of Aluminium Profile | Building, Industrial, Machinery, Automation parts, CNC |

| Certification | ISO9001 |

| Shipping Term | EXW, FOB, C&F or others can be discussed |

![]()

![]()

![]()

Frequently Asked Question:

Q1. What is required of RFQ?

1) 3D formats with .stp.(preferred) igs,.prt.

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and Year)

Q2. How do you ensure product quality?

Gennki applies assessment, planning, monitors every single process. Some bullet points:

1) Apply APQP Product development analysis

2) Lay emphasis on prevention and planning

3) Quality Criteria (ISO and TS 16949)

Q3. How do you ensure on-time delivery?

1) Detailed planning, details per hour/person/machine number/stakeholder…

2) Main material is managed efficiently

3) Daily progress meetings, a recovery plan will be reviewed by the management team once any key chain is a delayed.

4) If a delay happens on delivery in the course, extra hours will help to turn it on schedule

Q4. How can you if we don’t have the CAD data?

Gennki is able to generate the CAD for your review and approval in terms of your 2D sketch, or certain samples.

Q5. Can we test the plastic injection mold?

You are always welcome to the company with us to try the molds in place in person. The testing video can be supplied for your checking with your absence.

Q6. How long does an injection mold last?

Generally, a plastic injection mold could complete anywhere between 100,00 to 1 million (or sometimes somewhat more than a million) cycles in its lifetime, so it's subject to customer’s expectancy.

Q7. How about your guarantee or aftersales?

The worn-easily spare parts will be freely provided during the warranty period. Gennki’s strategic associated American mold shop will assist you to handle the modification change if needed after the delivery.

Q8. How Can I visit your company from abroad?

Easy to find, you may take an international flight either land at PVG Airport or Hongqiao Airport from your workplace. The nearby high-speed train station to Hongqiao Airport will facilitate your trip to elsewhere in China.