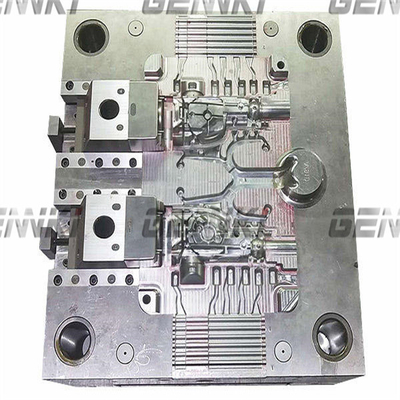

DIN AISI Aluminum Die Casting Parts Dievar Tier One Alloy Mold

| Place of Origin | China |

|---|---|

| Brand Name | Gennki |

| Certification | ISO9001 / TS 16949 |

| Minimum Order Quantity | 1 mold |

| Price | discuss base on certain RFQ |

| Packaging Details | plastic film wrapped or vacuumed, and sustained in the wooden crate |

| Delivery Time | 45 days~60 days |

| Payment Terms | T/T |

| Supply Ability | 60 sets/Monthly |

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum | Type | A380 Or ADC 12 |

|---|---|---|---|

| Process | Aluminum Die Casting | Mold Steel | H-13 Or Dievar |

| Surface | Anealing | Standard | DME And Hasco |

| Design Software | Solidworks, Proe, Catia, UG | Compatible Format | Iges, Prt, Step |

| Incoterm | FOB | ||

| Highlight | DIN AISI Aluminum Die Casting Parts,Tier One Aluminum Die Casting Parts,Dievar aluminium alloy casting process |

||

Precise Aluminum Die Casting Service for diverse industries

The die casting die, or mold, is a closed vessel into which molten metal is injected under high pressure and temperature, then rapidly cooled until the solidified part is sufficiently rigid to permit ejection from the mold. This is one of the experienced capabilities in Gennki group that we are granted a lot of assignments from customers across the world.

| Process Technology | lost wax casting process / soluble glass casting process / silica sol casting process/ die casting process /sand casting process / + Precision CNC Machining + Surface Treatment |

| Material that can cast | (1)grey iron, ductile iron , pig iron |

| (2)carbon steel, stainless steel, alloy steel | |

| (3)aluminum alloy, aluminium, A380, aluminum 6061 | |

| (4)zinc alloy ,copper, brass, bronze etc | |

| Size | Customized as customer's drawings |

| Weight Range | 0.02-20 KGS |

| MOQ | 500 Pieces |

| Tolerance | ±0.05mm |

| Surface Treatment | Heat Treatment, Polishing, Plating, Machining, Anodizing, shot, sand blasting, zinc plated, oxide, galvanized etc. |

| Testing | Three coordinate measurement machine for testing. |

| Certification | ISO9001:2008 |

| Standard | ISO , DIN, AISI, ASTM, BS, JIS, etc. |

![]()

![]()

![]()

Frequently Asked Question:

Q1. What is required of RFQ?

1) 3D formats with .stp.(preferred) igs,.prt.

2) 2D drawing for tolerance/material/surface finish/test requirement/regulations

3) Quantity (by order, month and Year)

Q2. How do you ensure product quality?

Gennki applies assessment, planning, monitors every single process. Some bullet points:

1) Apply APQP Product development analysis

2) Lay emphasis on prevention and planning

3) Quality Criteria (ISO and TS 16949)

Q3. How do you ensure on-time delivery?

1) Detailed planning, details per hour/person/machine number/stakeholder…

2) Main material is managed efficiently

3) Daily progress meetings, a recovery plan will be reviewed by the management team once any key chain is delay.

4) If a delay happens on delivery in the course, extra hours will help to turn it on schedule

Q4. How can you if we don’t have the CAD data?

Gennki is able to generate the CAD for your review and approval in terms of your 2D sketch, or certain samples.

Q5. Can we test the plastic injection mold?

You are always welcome to the company with us to try the molds in place in person. The testing video can be supplied for your checking with your absence.

Q6. How long does an injection mold last?

Generally, a plastic injection mold could complete anywhere between 100,00 to 1 million (or sometimes somewhat more than a million) cycles in its lifetime, so it's subject to customer’s expectancy.

Q7. How about your guarantee or aftersales?

The worn-easily spare parts will be freely provided during the warranty period. Gennki’s strategic associated American mold shop will assist you to handle the modification change if needed after the delivery.

Q8. How Can I visit your company from abroad?

Easy to find, you may take an international flight either land at PVG Airport or Hongqiao Airport from your workplace. The nearby high-speed train station to Hongqiao Airport will facilitate your trip to elsewhere in China.